More technical information

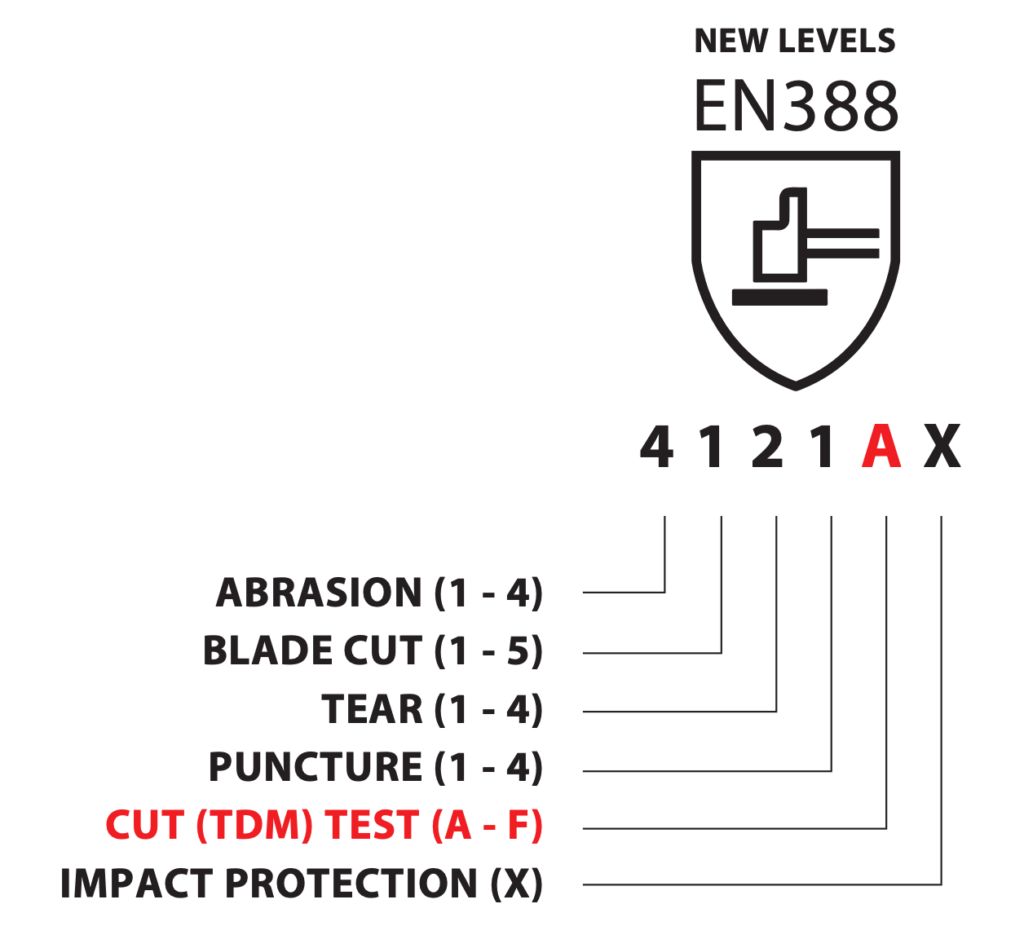

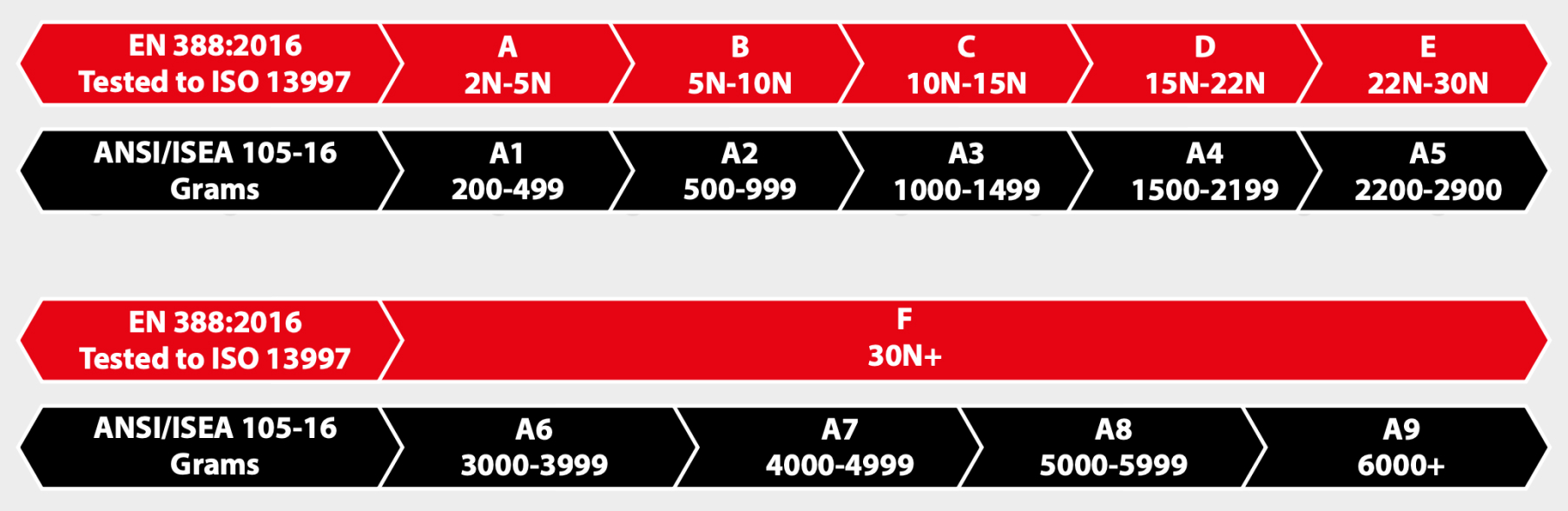

2 Newton = 203 Grams to Cut

Light Cut Hazards

Applications:

Automotive manufacturing, appliance manufacturing, metal stamping, sheet metal handling, construction, extruded plastics.

5 Newton = 509 Grams to Cut

Light/Medium Cut Hazards

Applications:

Automotive manufacturing, appliance manufacturing, sheet metal handling, construction

10 Newton = 1019 Grams to Cut

Medium Cut Hazards

Applications:

Automotive manufacturing, appliance manufacturing, metal stamping, sheet metal handling, construction

15 Newton = 1529 Grams to Cut

Medium Cut Hazards

Applications:

Automotive manufacturing, appliance manufacturing, metal stamping, sheet metal handling, construction, extruded plastics

22 Newton = 2243 Grams to Cut

Medium/High Cut Hazards

Applications:

Automotive manufacturing, appliance manufacturing, metal fabrication, metal stamping, sheet metal handling, steel handling, steel processing, construction, extruded plastics, recycling

30 Newton = 3059 Grams to Cut

High Cut Hazards

Applications:

Metal fabrication, metal stamping, steel processing, steel handling, recycling

Legend:

N = g × 0.00981

force = mass × 0.00981

EN 388: measures

FORCE using Newton

ANSI/ISEA 105: measures

MASS using grams

15 Newton = 1529 Grams to Cut

Medium Cut Hazards

15 Newton = 1529 Grams to Cut

Medium Cut Hazards

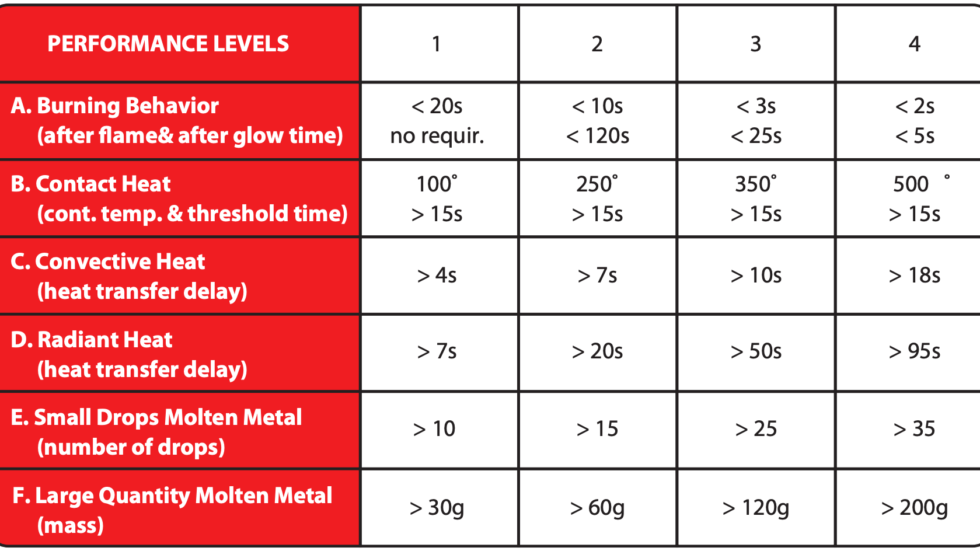

Resistance to convective cold (performance level 0 to 4)

This is based on the thermal insulation oproperties of the glove which are obtained by measuring the transfer of cold via convection

Resistance to contact cold (performance level 0 to 4)

This is based on the thermal resistance of the globe material when exposed to contact with a cold object

Penetration by water (0 or 1)

0 = water penetration

1 = no water penetration

Note: S = seconds g = gram

Thermal transmittance is measured using test method GB/T 11048-2008 Method B. Thermal transmittance (Watts per square meter Kelvin) is defined as the rate of transfer of heat through one square meter of a structure divided by the temperature across the structure. The higher the value, the more transmittance or heat dissipation is occurring. Testing according to this well established method for textiles has shown that the addition of Kyorene® to the fabric has 1.5 times more thermal transmittance than the fabric without. In plain English, the data shows Kyorene® and Kyorene® Pro to provide for a cooler and less sweaty hand inside a glove.

Thermal transmittance is measured using test method GB/T 11048-2008 Method B. Thermal transmittance (Watts per square meter Kelvin) is defined as the rate of transfer of heat through one square meter of a structure divided by the temperature across the structure. The higher the value, the more transmittance or heat dissipation is occurring. Testing according to this well established method for textiles has shown that the addition of Kyorene® to the fabric has 1.5 times more thermal transmittance than the fabric without. In plain English, the data shows Kyorene® and Kyorene® Pro to provide for a cooler and less sweaty hand inside a glove.

© 2025 All rights Reserved.